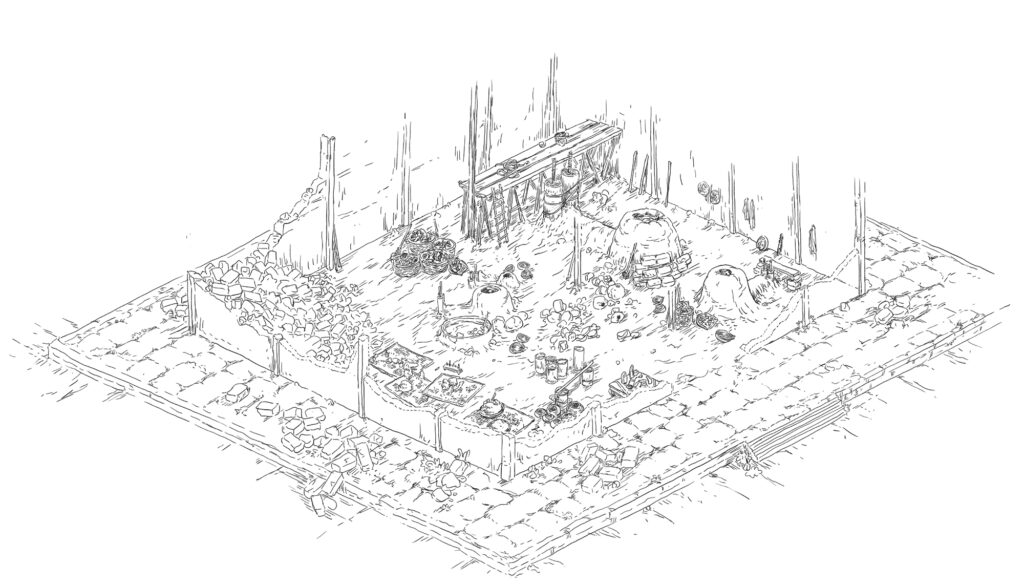

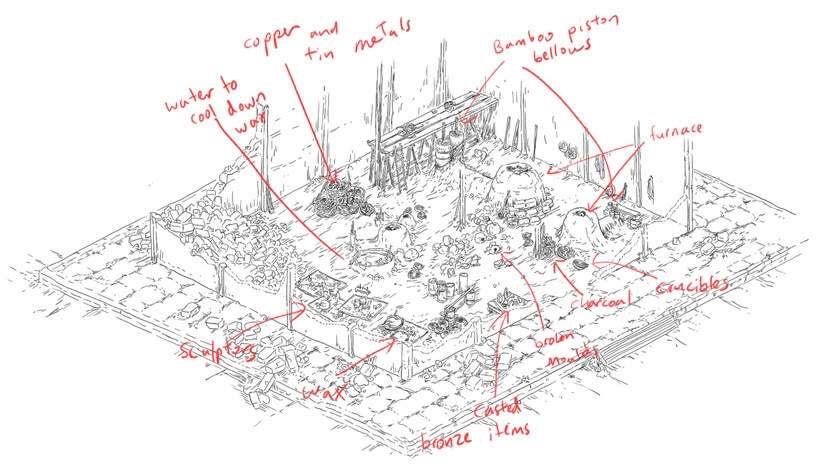

This is my first attempt at drawing a foundry, largely based on what I know of Southeast Asian metallurgy.

This was a little daunting to do because there’s so much technical knowledge for metallurgy and also technical knowledge from Southeast Asia history! Which was both challenging and exciting to learn and understand for me.

So this post would be me sharing my thought processes behind this drawing.

So firstly, this image is a layout map for something for a tabletop RPG adventure, which Zedeck and I will work on, Zedeck hasn’t seen this drawing nor worked on it so it likely will change in it’s final form in the future.

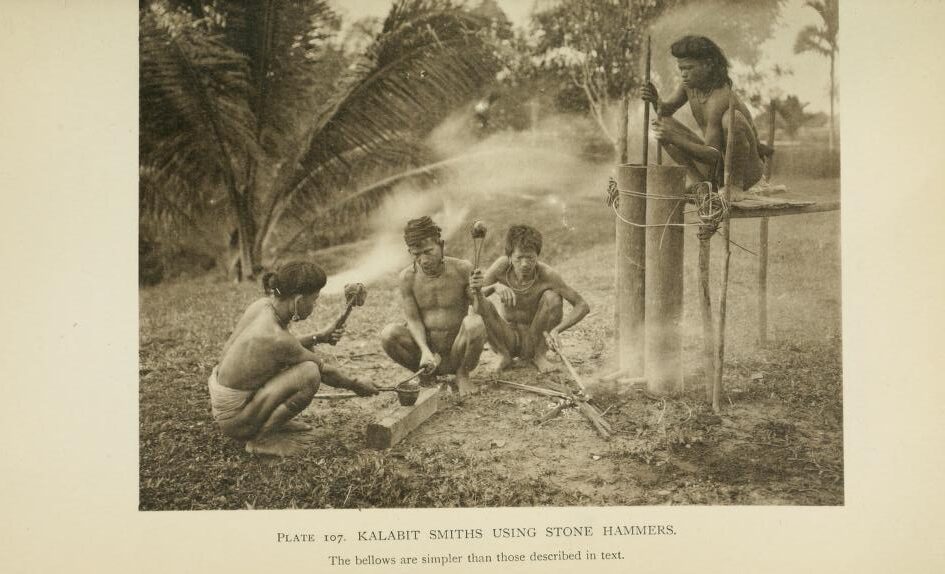

Piston Bellows

The biggest feature of the foundry is the furnace and the bellow system. What’s depicted here are piston bellows which are fairly common in SEA.

The cylinders are made of wood/bamboo, while the pistons themselves have feathers or some similar uhm… fluffy? material which would force air down while still allowing fresh air to go into the cylinders. The pistons would push down the cylinders, delivering gushes of air to the furnace.

Here’s a video of a Bidayuh piston bellow in action:

Clay Furnace

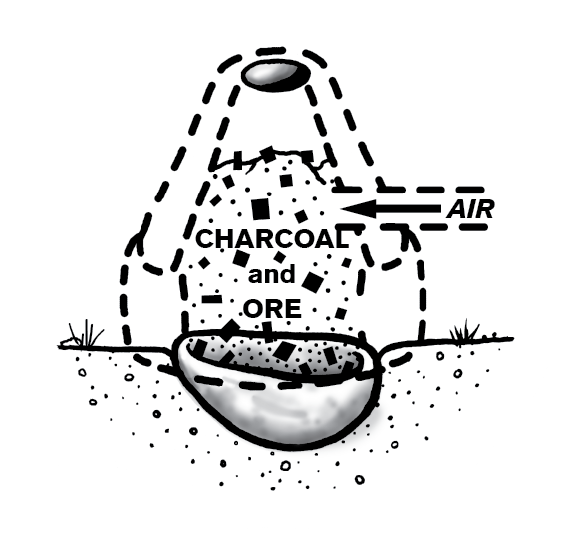

The furnace is a clay furnace, also common in Southeast Asia. I think it’s called a bloomery furnace.

These furnaces would both be used for smelting metals out of ore.

This diagram above shows both the technology of metallurgy but also the crucibles at the bottom, these are ceramic and also point to a technology/understanding of ceramics that can withstand high heat.

If I am not wrong, that is for copper and other metals of lower heat, iron would still be in a clumpy state which they will just dig out by breaking a small hole in the furnace.

Here’s a video of someone smelting iron from iron ore:

Actually his whole series is great if you have time to check it out.

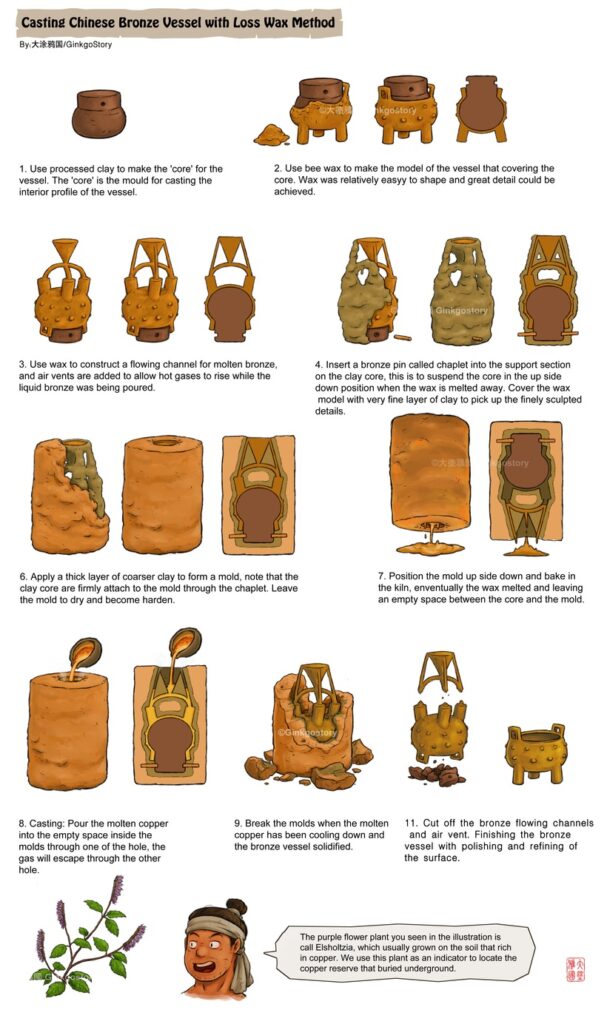

Lost Wax Casting

Lost wax casting was a common technique for casting wax around the region too, and that involves sculpting wax, making a clay mould out of the wax and then melting out the wax to get an empty mould.

Here’s an awesome comic that details the process. It’s by Gingkostory, they do historical illustrations with a manga twist.

What’s really interesting is the last bit about how people locate metal ores, via where the flowers grow.

What I know of Southeast Asia, or Malaysia at least is true to it’s magic loving form, they get shamans/magicians to help them locate metal ore. (link)

An image from this series of photos about a workshop in Vietnam still practising Lost wax casting. (Source)

I wonder if only wax was used or any type or sculpt-able and melt-able resin was used, different types of resins was such a common object used in so many things.

And that’s that, my first attempt at illustrating a Southeast Asian foundry.

Text by Munkao. This post was originally published on October 2, 2020 on the A Thousand Thousand Islands Patreon.